- Standout technology in QR code recognition system and motion control system

Established in 2008, MAROROBOT TECH Co., Ltd. (CEO Deukgeon Kim, http://www.marorobot.com) is Korea’s industrial robot expert. Currently, the company’s main products include the smart logistics robot, ‘M3;’ 3-axis positioning semiconductor inspection equipment, ‘R-PASS;’ surface resistance measuring equipment; and control boards.

MAROROBOT TECH completed development of the QR code-type smart logistics robot, ‘M3,’ and has begun actively marketing it since last year. Currently, the company has supplied their products to JVM, a subsidiary of Hanmi Pharmaceutical and ASE Korea.

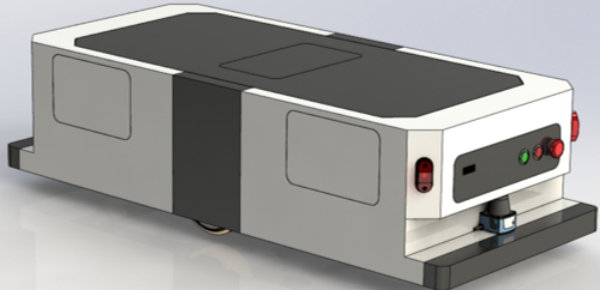

▲QR code-type smart logistics robot, ‘M3,’

M3 is a logistics robot that recognizes the QR code, understands the direction and positioning of the robot, and can work independently of any external controls. It can also be controlled by an external computer. The location information technology obtained using QR code recognition produces more accurate location and navigation functions that are far superior to the current Landmark method. The QR code is attached to the bottom of the product in such as way to prevent its damage in a warehouse, on a forklift, or through human carelessness.

The M3 robots released to the public last year were able to lift loads of up to 200kg and 400kg, but the new releases can lift loads of up to 1ton. The average speed of the robot is 30m per minute, with a maximum speed of 48m per minute. It is Wi-Fi supported and, unloaded, the robot can operate up to 12 to 15 hours.

▲M3-1000

The robot can be remote controlled by Wi-Fi and can be used as a standalone or network integrated management type. It comes equipped with photo sensors; LIDAR and bumper sensor can be added as options.

One highly appreciated feature of the M3 is that it can be used in different types of spaces and is not limited to space constraints, as it does not travel on a pre-designated path but rather travels on a user designated path. Current logistics robots use a magnetic system, which limits their movements to specific areas, so in order to change the path of the robot, a new magnetic line must be installed. The QR type method, in contrast, is able to travel according to the user’s desired path. The M3 robots can be put to work in several factories and controlled simultaneously with the appropriate software, or they can be commanded individually. The M3 control software supports map editing functions, QR code Tag editing functions, robot management functions by IP, and real-time robot monitoring functions.

MAROROBOT TECH is actively pursuing the global market, such as by presenting its smart logistics robot at the 2016 Guangzhou logistics exhibition. In particular, the company is eying – and vying for a piece – of the fast-past growth of the industrial robot market on the heels of the government’s ‘China Manufacturing 2025’ policy announcement.

▲선반 밑으로 들어가 물건을 들어올리는 M3.png

In addition to M3, the company offers 3-axis positioning semiconductor inspection equipment, surface resistance measuring equipment; and control boards. ‘R-PASS,’ the 3-axis positioning semiconductor inspection equipment, is used by EMC testing laboratories for development or debugging that need to establish EMC measures at the PCB stage. The company has developed hardware and software in partnership with IOSOFT and is producing semiconductor inspection equipment. Diversification of the PROBE and 3D expressions obtained through movement of the XYZ axes ensure a more convenient user environment and more accurate data.

MAROROBOT TECH is expanding their technological skills in other areas; for example, they are currently developing a drone that comes equipped with an obstacle recognition function. 75% of the company’s workers are concentrated on research and development, attesting to the company’s enormous strength in this area.

J Yoo robot3@irobotnews.com